Liquid silicone injection moulding is mainly based on the same technique as die-casting but the liquid material consisted of two components is pushed to a mould when cold and so called vulcanization happens in the heated mould.

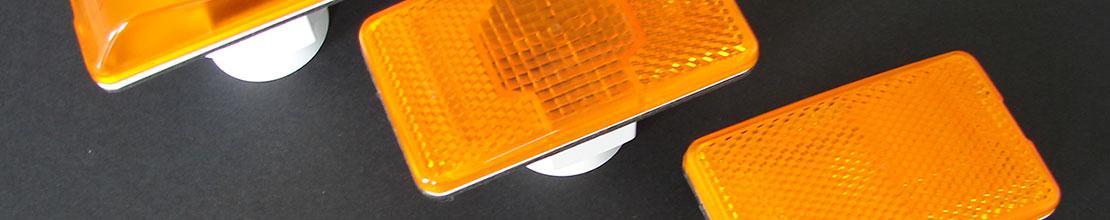

The advantages of silicone include its durability in high temperatures, flexibility and resistance to chemicals. Especially good resistance to UV radiation is considered as one of the best advantages of silicone. We are specialised in manufacture of optical cilicone products.