In die-casting, hot moulding compound is moulded with pressure into a closed mould. That is why we try to minimize the number of components and joints of the product designed to die-casting. Usually we make a finished product or its component by die-casting – so you do not need subsequent processing.

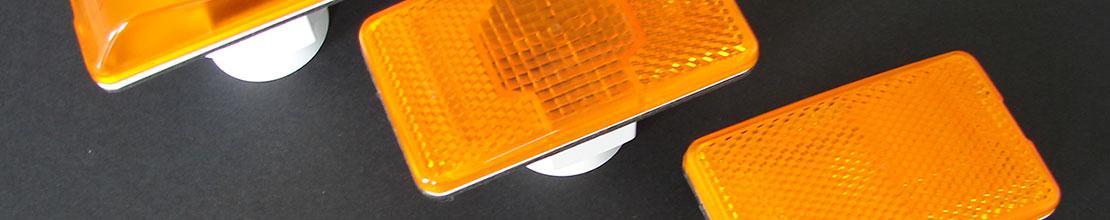

Our equipment per worker is extensive and modern – its mould clamping force is 20-650 tons. The weight of the products we manufacture varies from under one gram to 2.5 kilograms. We have extensive experience in technically and especially optically demanding components. You can also get 3K products and insert products e.g. with metal inserts.

We use all common types of plastic compounds, additives and colouring agents without forgetting speciality plastics. Already in design phase, we try to optimise product material to suit application and conditions of use.

Our staff working in the die-casting department includes professionals in this field and they enable flexible and cost-effective production.